Valk Welding invests in a strong connection with its customers, not only through the welding robots its delivers but especially with the service support it provides.

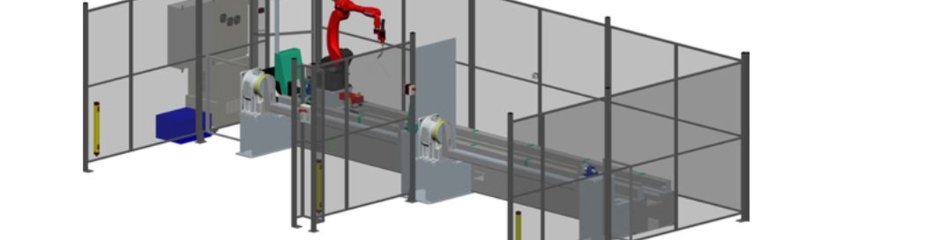

Customers can therefore count on full support in the areas of welding, robotics and programming both in the start-up face and also thereafter. This makes it pos-sible for most customers to get high returns on their investment. "That impression has not escaped our view", says Dieks Prenger, managing director of Tubeworkx. This Almelo-based parts supplier for the central heating industry and the auto-motive, truck & bus, medical and hydraulics sectors, which has already several Yaskawa Motoman cells in use, invested this year in a Valk Welding welding robot cell. This consists of a Panasonic TA 1800 welding robot on a track that serves 2 work stations with horizontal rotating positioners, on which parts with a maxi-mum product length of 2,500 mm are welded.

Dieks Prenger, who took over the company with partner Marc ter Horst in 2004 and shifted the focus under the new name Tubeworkx to tubular products, plans to be at the cutting edge of production technology in this market. "We have built up a superb competitive position in relation to the low-wage countries through working 24/7, high reliability of supply, absolutely watertight products and just-in-time delivery", explains Dieks Prenger.

The company had doubts about staying with its current supplier to increase its capacity because of its experiences with mainly the service support it provided. Dieks Prenger: “The impression that Valk Walking is the market leader was immediately underlined by the first weld test . Communication was direct and quick, the welding quality of the test pieces was perfect and the demo in Alblasserdam made a very good impres-sion to us. The new welding robot gives us the latest technology, which not only offers more functionality but also makes the system easier to operate then our present ones."

Tubeworkx is now using the new welding robot for 25 different products. "These are all regular orders that we have programmed on-line. The Valk Welding systems make it pos-sible for us to re-use the existing programs without applying any corrections. We would like to automate the welding for even more products this way, but we haven't got the space. As soon as the new building is ready there will be nothing in the way of further expansion with Valk systems," predicts Dieks Prenger.